OLED Lighting vs. OLED Display: The Difference Matters.

If you are not carrying an OLED display in your pocket already, you likely will be soon. Some mobile phones already use OLED screens and The Wall Street Journal recently reported that Apple plans to use OLED displays in all their phones by 2020. But mobile phones and lighting are completely different things.

In an OLED display, millions of tiny carbon-based light-emitting pixels can be individually addressed to provide video and other content. But what if happens when you make one very large OLED pixel? It’s still a carbon-based light emitting device, but now you can use it for general and specialty illumination.

Brightness, longevity

While OLED lighting has benefited from the investment in OLED display, OLED lighting has several performance and cost challenges that are surprisingly different from display, including:

- Higher brightness levels, 8X – 20X than that of most displays

- Longer lifetime requirements (10 years)

As OLEDs get brighter, they typically lose longevity. And yet, this combination of brightness and lifetime must be delivered, and with today’s technology is delivered, for lighting and at a markedly lower cost point than display.

Displays operate primarily in video mode with subpixels on the micron range; a missing subpixel due to a short is generally not detected by the human eye. The defect is just too small and obscured by the rapid change in image. But in OLED lighting, a short will cause a large, noticeable dark spot and may ultimately cause the entire light panel to fail. Panel designs and manufacturing controls specific to OLED lighting are developed to manage such a failure mode.

Natural light and biology: The link

Why is this? Light impacts circadian rhythms, which play a role in blood sugar levels, and leptin, the hormone that helps people feel full after a meal. Natural daylight can help to maintain circadian rhythms, while blue light, such as those in LED lights and computer screens, can disrupt this rhythm.

While daylight is ideal, this presents challenges for office design and budgets, and for many latitudes and climates.

What’s more: traditional office design puts executives around the exterior in windowed offices, while employees who typically spend the most time at their computer screens are clustered in the interior under LEDs or fluorescents. This dichotomy can significantly impact productivity from the workers your business depends upon.

You want it white

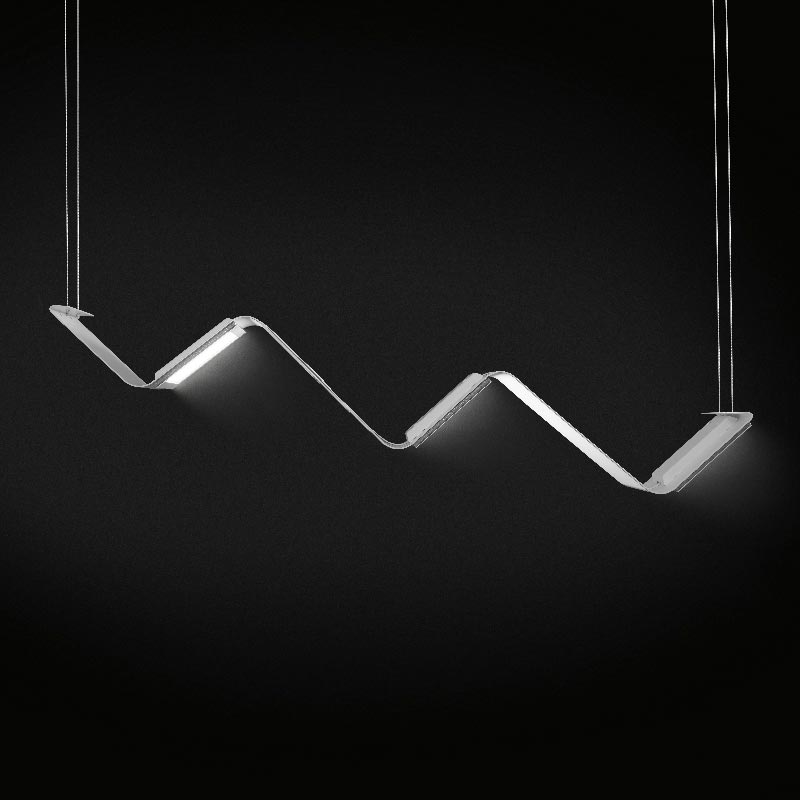

If you’ve ever taken a good look at the lighting in a restaurant, a store, a waiting room or office, you’ll notice some lights look warm, tending towards amber, and others are almost blue or green tinged. They don’t match. The designer did not intend for that experience. It is the variability in fluorescent or LED light sources. Manufacturing process controls enable OLED white panels to match extremely well creating a homogeneous effect in large installations.

The reliability demands are not just about performance failures—lighting panels are usually used in clusters and they must match each other as they age. White OLED lighting has all the colors in one OLED structure. Displays use individual red, green and blue OLED subpixels with each one controlled individually. Stacking the color emitters creates unique optical, chemical, semiconductor physics and manufacturing challenges. It’s a balancing act.

But it’s all leading to some very good news

The OLED display industry has made significant progress in materials, substrates, and processing that benefit OLED lighting. And we’ll continue to meet those challenges specific to OLED light so it can be experienced as it was meant to be.