Machine Vision Inspection Could See Greater Accuracy with OLED Lighting

By Dr. Kathleen Vaeth – Director of OLED UX, OLEDWorks

It’s no surprise that when you buy a product or a tool, you expect it to work correctly and be free of defects or errors. We can trace the history of quality management processes and industry standards like ISO today back through time as far as the Medieval artisan guilds and beyond. But when looking to the business of tomorrow, inspection and quality management can be very time-consuming and expensive when done by the human hand. That is where machine vision inspection comes in, and the lighting integral to its success.

What is Machine Vision Inspection?

Machine vision inspection is the use of automated means to detect defects, contaminants, positioning errors and information in commercial products or their parts. It is particularly useful for repetitive and detailed work where inspection by human vision can lead to fatigue and subsequent drifts in criteria or errors, impacting accuracy, consistency, and yield.

Although the practice has been around for over one hundred years, use has become more widespread over the past several decades due to improvements in optical detection technologies and computational power that make accuracy, speed, robustness, and stability in manufacturing better than human inspection.

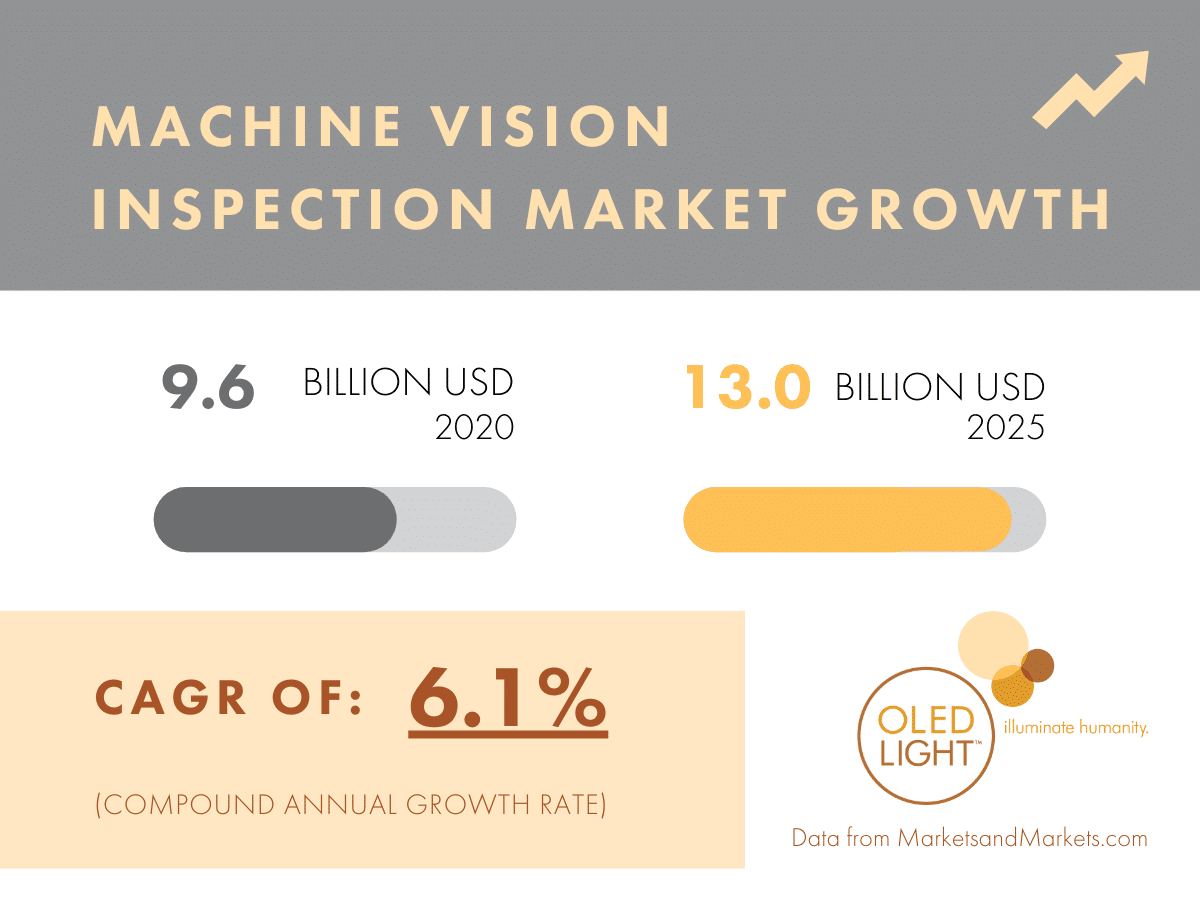

With the growth of artificial intelligence and the internet of things (IoT), the global machine vision market is predicted to grow from 9.6 billion USD in 2020 to 13 billion USD in 2025.

Choosing the Right Light for Machine Vision Inspection

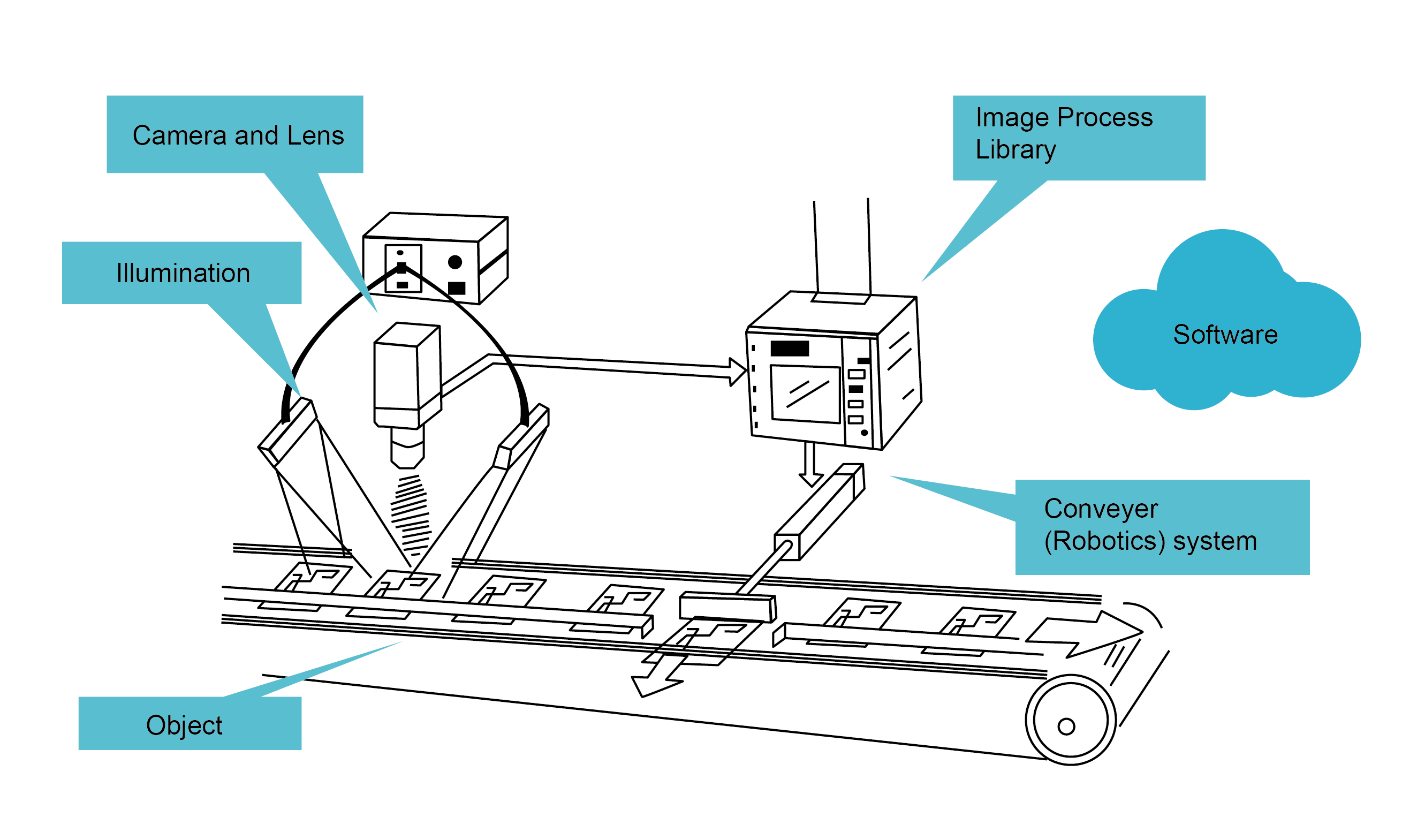

A machine vision system consists of an imaging system such as a digital camera, a light source, optics, and a computational system. The setup must be designed, optimized, and often customized for the material of interest and type of inspection being performed to achieve accurate, robust, and repeatable results at acceptable throughput.

The light source type and positioning can impact all these factors and must be selected appropriately to be able to identify defects quickly and efficiently through image processing. For positioning, backlighting facilitates dimensional measurements of parts, while front lit lighting can facilitate detection of surface defects such as scratches or pits.

Example of a machine vision inspection system (Courtesy of Innomiles.com)

Lighting is also selected to appropriately enhance the contrast of features of interest compared to other unimportant aspects, either through the position of the source relative to the detector, optical characteristics and structure of the illumination, or light color. For example, if red printing on a label of mixed text colors is under inspection, use of a red light will accentuate that text and minimize other colors, increasing the speed and accuracy of the overall process.

Nonuniformities in the light source can also lead to false positives in inspections, and therefore a high degree of illumination homogeneity is desirable. The light can be operated continuously but is sometimes strobed to help with computational speed. Computational speed is how long the computer takes to perform the analysis of the image, which in turn increases the throughput of the inspection process.

Equally important to the quality of light is the form factor of the source and how easily it fits in the overall inspection station. When it comes to the design of inspection stations, sometimes the light source is thought of last, leaving tight spacing or requiring the light source to fit on a curve.

For particular inspections, there is one other key consideration when choosing the ideal light source: heat. Heat generation from light sources can be important for inspections of food and biological or medical samples that are often temperature sensitive; this impacts how close the light can get to the inspected item, as well as what kind of cooling or other air circulation systems might be required.

OLED Lighting Meets Machine Vision Inspection Needs

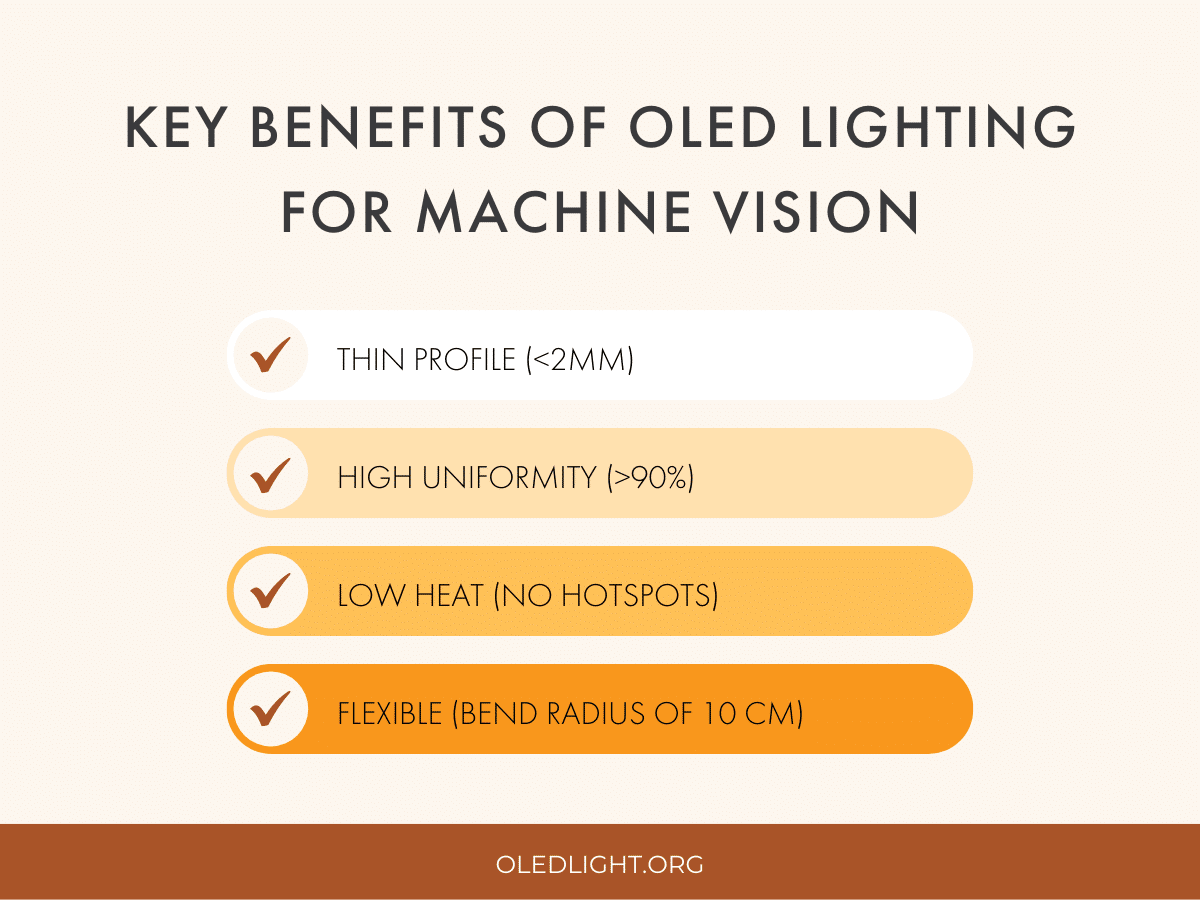

OLEDs provide a unique option for lighting in machine vision inspection. Through a combination of thin form factor, uniform emission over a large area, and low heat generation, OLEDs give access to new markets that previously were more challenging to address with machine vision inspection using other lighting technologies.

The naturally diffuse emission of OLED lighting results in illumination quality that is incredibly uniform, typically reaching over 90% homogeneity across the surface of the panel. This uniformity means that the imaging and computational system is more likely to register fewer false positives, increasing the accuracy of the inspection. OLEDs can be operated in a pulsed or continuous mode, giving flexibility to tailor the lighting to the specifics required of the inspection.

With a total thickness of less than two millimeters, OLED lighting panels can fit into the tightest of spaces, widening the options for fixture design. Bendable OLED lighting panels such as the LumiCurve Wave by OLEDWorks, which is fabricated on Corning® Willow® Glass, are capable of flexing to a minimum bend radius of 10 centimeters. With bendable OLED lighting as an option, the light can be oriented to fit the geometry of the part more easily to uniformly light curved objects that are being analyzed.

LumiCurve Wave by OLEDWorks, on bendable Corning® Willow® Glass

In addition to the naturally homogeneous emission of light, OLED lighting panels do not have local hotspots, and do not generate much heat during operation. For inspections involving temperature-sensitive items such as food, or biological and medical samples such as vaccines, this lack of localized heating means that the panels can be placed closer to the product without risk of damage. This could result in better illumination and a more compact fixture design, which in turn increases the accuracy of the inspection.

With greater adoption of OLED lighting solutions for machine vision inspection, manufacturers could see greater accuracy, more design freedom, and decreased risk surrounding temperature-sensitive goods. With the market set to expand considerably over the next five years, now is the perfect time to adopt OLED lighting for machine vision inspection needs.

Make sure to subscribe to OLEDLight.org to stay up to date on the latest OLED lighting news, innovations, and new products.