On-Demand OLEDs in Any Shape and Size: Inuru Announces New Pilot Line

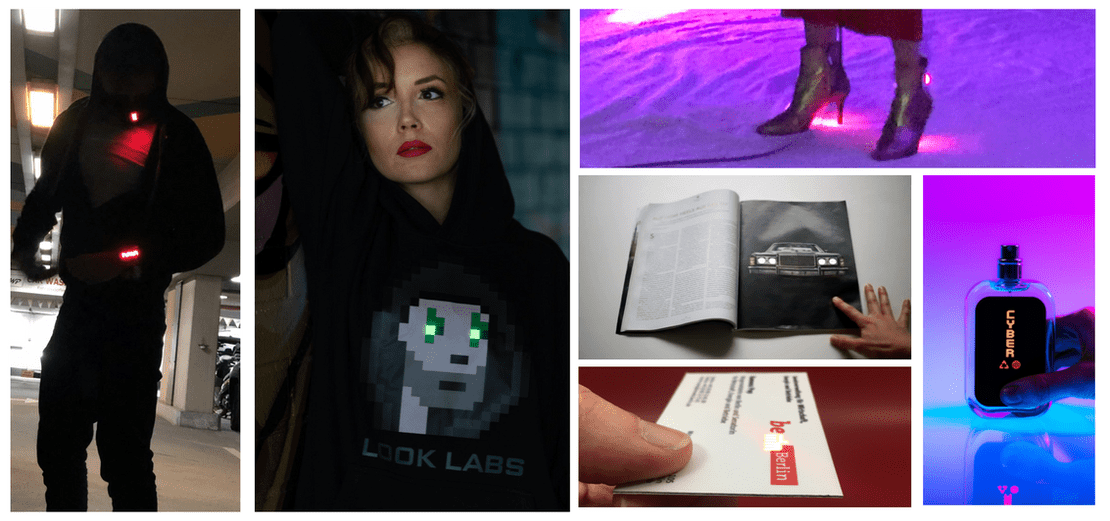

Recently, OLED lighting manufacturer Inuru announced their new pilot line, capable of producing OLED lighting in any shape and size on-demand. Primarily, this technology’s purpose is for labels and packaging, fashion, and wearables.

Check out an excerpt of Inuru’s announcement below to learn more.

Inuru today announced a major milestone in OLED fabrication with establishing the capability to print OLED in any shape and on demand. With the new freedom of shape and size Inuru customers can finally benefit to illuminate any artwork and design they need and do not have to adapt to standard parts.

Light in Any Shape, Paper-thin

Inuru has successfully established a new pilot line in Berlin Adlershof, that allows to print light in any shape and on demand. This ceases size limitations and allows fully custom made light effects not only for Inuru’s demanding packaging and labelling customers.

To illuminate shapes or surfaces companies typically use LEDs solution today. To illuminate a shape LEDs require expensive light guides or projection areas, that typically have a distance of multiple millimeters between the LED light source and the projection area.

This make the lighting devices bulky and expensive, despite the cheap unit cost of the single LED itself. Also homogeneity of the illumination is not ideal with clearly visible bright spots that can only be eliminated with adding more LEDs and thus multiplying costs.

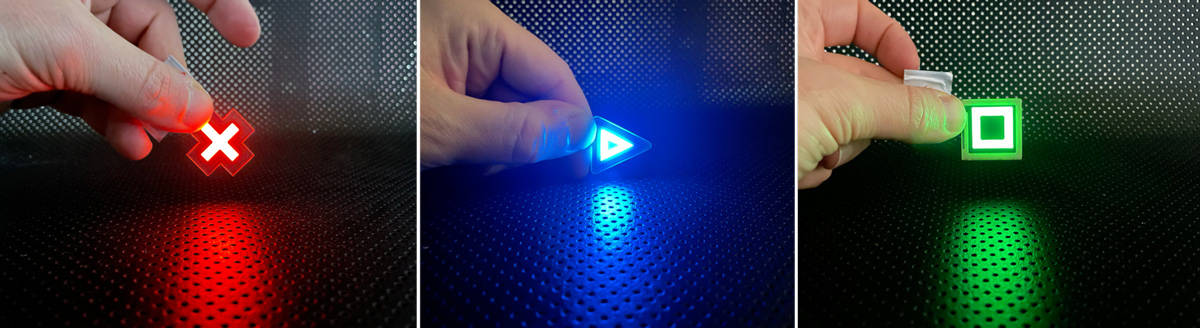

OLED is paper-thin and does not require light guides. With the latest achievement Inuru can print the precise shape of light in a similar fashion like color is printed on paper today.

This decreases the size of lighting applications to 0.2mm compared to multiple mm that are needed for todays LED and light guide solutions. Also the homogeneity is superior since every part of the surface directly emits light.

Novel Design Possibilities

With the ceasing of size limitations Inuru’s customers in Packaging and Labels can finally illuminate the size of logo, artwork, etc without the need to adapt it to standard panels.

The paper-thin light sources are ultra-bright and energy efficient at the same time. They that can even be powered with a thin printed battery. This enables the integration of light and – coming with it – digital effects everywhere where space is limited.

Because of its energy efficient build, no hidden batteries are needed and the full technology can still be delivered in a paper thin label. This also bear the potential for the integration of Inuru OLED solutions into wearables, fashion and automotive interior lighting.

Read the full press release: Free Form OLED announced. Inuru achieves milestone in production of light and displays on demand